|

| August 06, 2013 | Volume 09 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

How to use differential pressure sensors to measure the hydrostatic level of a liquid in a vented or sealed tank

Differential pressure transmitters are reliable, cost-effective instruments to measure the hydrostatic level of a liquid in a vented or sealed tank.

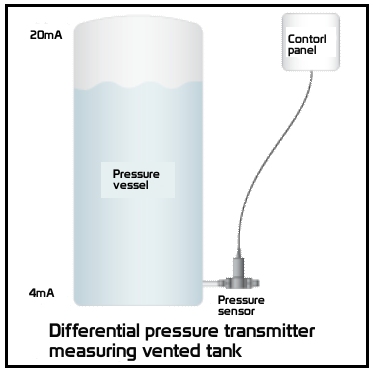

For a vented tank, the pressure transmitter should be mounted to the bottom (see graphic to right). Typically, the transmitter will be threaded into the outlet line of the tank, a side bung, or flange. Since a pressure transmitter provides a linear output signal, such as a 4mA to 20mA signal from zero pressure to the full-scale pressure, the level can be monitored based on the liquid density and the height of the tank.

For example:

Density of water at 4 deg C = 1

Height of tank = 35 ft = 420 in.

27.68 in. of water column = 1 PSI

(420 in. / 27.68 in. of water column) x density of 1 = 15.17 PSI

Here, the height of the tank is converted into a measurement range. Since the pressure cannot exceed the height of the tank while considering the density of the liquid, the user can use the maximum amount of signal for the specified range.

The selection of the output signal is always application specific. A 4mA to 20mA output signal is the most common in monitoring applications that require long-distance transmissions. The current can be read at the controller without signal loss for hundreds of feet. The downside is that the sensor will require more power and, more importantly, current. For either battery-powered or solar-powered applications, voltage output signals are ideal. Typically, the solar panel will be located close to the pressure sensor, so there is no signal loss in the cable.

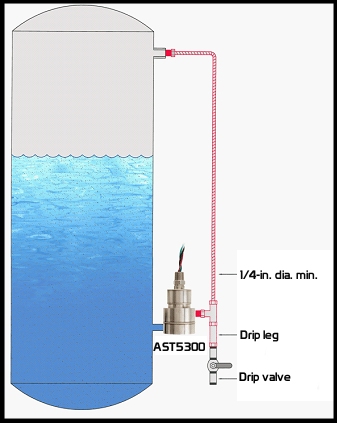

For liquid level measurement in sealed tanks, differential pressure transducers must be chosen specifically for a hazardous or non-hazardous application. The high/upstream process connection is installed at the bottom of the tank, with the low/downstream side installed with 1/4-in. tubing (minimum) connected to the top of the tank (see graphic below). The larger the pipe diameter, the lower the potential of a capillary effect from moisture buildup.

The AST5300 Wet/Wet Differential Pressure Transmitter from American Sensor Technologies offers both a 5-PSID and 10-PSID measurement range for level measurement of sealed and vented tanks. With no oil-filled cavities and no internal o-rings to fail, the AST5300 is ideal for food and beverage, oil and gas, fluid power, pharmaceuticals, and semiconductor industries and cold ambients.

Certain applications use pressure or vacuum pressure above the liquid. In these cases, the pressurized line can be connected directly to the low side of the pressure sensor.

In applications where liquid from the tank or condensation might build up in the low line, a drip leg and drain valve are recommended to maintain accurate level measurement. The drip leg allows incidental condensation to accumulate and re-evaporate without affecting the transducer readings. The drain valve allows for quick maintenance and draining of the line without sensor removal, saving time and money in the long run.

By understanding the maximum height of the liquid and its specific gravity, measuring liquid level becomes simple and cost effective.

Overall, differential pressure transducers have the advantage over top-mounted transmitters in sealed tanks in applications where the fluid is reflective, has foam, or is clear. Since the measurement is based on the physical force of the liquid on the diaphragm, there is less chance for error.

Source: American Sensor Technologies

Published August 2013

Rate this article

View our terms of use and privacy policy